Leather boots are among the few items of fabric that are unmistakably associated with raw denim.

Considerate fabrication, natural elements, a century-old visual appeal, and the assertion that boots are usually a mix of fashionable and operational promote the way for the ordinary denim head and his lasted calfskin to be cuffed.

And, as is common in the denim industry, it’s easy to get caught up in the frenzy of jargon. That’s where we can help.

Take note of our detailed summary of the footwear industry’s most frequently used welts, whether to merely outwit your forum pals or to genuinely find the right set to meet your requirements.

What Is The Biggest Difference between Bench Welt and Goodyear Welt?

Table of Contents

The most significant distinction is, of course, the price. Everything can now be completely automated, which means humans don’t get to do more.

Each technique of sole sewing has benefits and drawbacks, just like everything else in life.

This frequently has an effect on the final product performance. In conjunction with cheap labor in Asian countries, cheap materials such as glue or even artificial leathers keep the cost down.

On the plus side, they are simple to create and manufacture.

The price rises as humans and artisans become more involved, but so does the effectiveness.

Bench Welted shoes are scarce from outside the bespoke world at the moment, but they are a piece of artwork that require hours of thorough artistry.

While not a precise indicator of value, a welted shoe is often superior to a cheaply constructed shoe.

Finally, some methods have distinguishing characteristics that you should look for. Some of them are greater comfort, lighter weight, and greater waterproofing.

What is Bench Welt?

Bench welting is the process of dragging the leather shoe arch over the last (the forms on which the shoes are made) and securing it with nails.

One of the most significant is that a bench welted shoe has a lovely shape that follows the curves of the last exactly.

The next step is bench welting, which involves hand stitching a strip of leather around the rim of the shoe. This is the base to which the sole and heel will be attached.

What is Goodyear Welt?

The Goodyear welt was devised in the mid-1800s by Charles Goodyear, Jr., son of Charles Goodyear, who created rubberized rubber, as a way to make leathercraft more convenient with few drawbacks in accordance with the construction reliability.

The welt is a band of content that is sewn around the bottom edge of the boot or shoe’s top half. A diagonal seam connects the insole, top, and welt.

As a padding, an inner layer – generally cork – is introduced between the insole and outsole, and the welt and outsole are joined with a quick stitch.

The end result of a Goodyear welt is that it is moderately effective at keeping condensation out, is easily resolable, and can be done by machine rather than by hand, lowering costs and cycle times.

The disadvantage is that it can be completed by machine rather than by hand. That means that even lower-tier shoes can be manufactured using Goodyear welt building, though many top-notch shoe and bootmakers do.

The effectiveness of a welt is largely determined by the quality assurance practices of the organization that manufactures the boot in the first place, so a company that is wanting to create and sell a large number of products may not be worried about producing the absolute best quality of product.

Bench Welt vs Goodyear Welt: What Similarities do They Share?

- There are a few subclasses of welted fabrication, but they all operate on the same premise.

- A rib is either sculpted into the insole (which is typically made of leather) or tethered to the insole (normally a rubber rib attached to a standard insole board).

- The top is then continued around the insole using glue or short-lived tacks.

- The upper is then sewn to the insole’s rib, along with a welt (a strip of thick leather).

- The welt is then pieced to the sole, which gives the welted shoe its appearance and name. Many shoes sold in stores now have an elegant trim called randing that mimics the look of a welted fabrication.

Bench Welt vs Goodyear Welt: What is the Comparison?

There are some things to consider here.

Canvas Ribs

To begin with, the canvas rib is just that: canvas. It’s just fabric. While theoretically quite sturdy, glue and fabric connecting the welt to the soles of the boot may not be the most long-lasting option available.

However, it is quick and effective, and it primarily involves machines.

Cost

The advantages of Goodyear welting over hand-sewn welting are that it is faster, less expensive, and simpler while still being of excellent quality all in all and resoleable.

This includes estimation of a decent quality pair of boots can be severely reduced while remaining sturdy and resoleable over time, causing them to be more affordable to people.

Prior to the invention of this faster process, all shoes and boots were handcrafted and thus quite expensive. This made them more difficult to obtain, so Goodyear welting enables more people to purchase more boots.

The Convenience

When you combine these two advantages, a bench-sewn welted boot has more leather to endorse your feet, whereas Goodyear welted boots have far less leather, more cork, and a more open area to support your feet.

As a result, the boot should be comfier.

As a result, the boot should be snugger. To be clear, I have been saying for years that comfort is open to interpretation, and I still believe this.

Also, people believe that poron or any artificial insoles are weaker compared to leather in terms of comfort and protection, so keep that in mind.

Nevertheless, these facts show how, in theory, a duo of hand-seamed welted boots should provide better support for your feet.

Hand welted boots, in concept, should be comfier and have much more leather among both your feet and the floor than most Goodyear welted shoes.

The Longevity

Another advantage of hand-sewn welted shoes would be that they are theoretically extra sturdy.

As previously stated, a canvas rib and glue clutching your boots next to each other are not as solid as thick leather. They should last longer between resoles and be less likely to fail than a duo of canvas-ribbed boots.

Goodyear welted boots appear to be more than sufficient for the ordinary person in real daily existence.

Let’s be honest: most of us who wear boots don’t really need them. We wear them and we like them and also have or want to have several pairs.

Craftsmanship

In my perception, the last real benefit of bench-sewn welted boots over Goodyear welted boots is the least impactful, but also the most significant.

Goodyear welt fabrication is a high-quality way of making shoes and boots because it is comparatively water-resistant, sturdy, and allows for resoles.

However, this procedure arose as a result of modernization and rapid manufacturing, and if you’re a fan of high-quality footwear and clothing, you’ll know that mass production is diametrically opposed to true craftsmanship and quality.

Hand welted boots require more time, effort, and skill to create. This is unmistakable.

It is not effortless to do, and even more difficult to do well. It also takes considerably longer than Goodyear welting. Goodyear welting can be completed in a matter of seconds.

Peng from Flame Panda (a local firm located in rural China) claims that his hand welting procedure with hand-sewn outsoles requires 2-5 hours to complete.

This would take approximately an hour just for the hand welting. Rizky from Onderhoud Handmade said that the sewing alone takes 1-2 hours. Show Goto of White Kloud also said that the procedure of welting with his hands takes two hours.

Try comparing this to how long the gemming process usually takes in Goodyear welts.

This additional time spent not only making the boots this way but also learning the craft demonstrates dedication, which is what truly pulls people to hand welted shoes.

This is why individuals who already own hand welted boots find it humorous when people claim that faults in brands like Red Wing, Wolverine, or Thursday boots are due to the fact that they are “handcrafted.”

Much of the fabrication with these manufacturers is done by machines. Handmade shoes are much more aesthetically pleasing.

Which one is Better? Why?

Believe it or not, there is a lot of misunderstanding and debate surrounding these shoe construction methods, owing to a slew of myths and misleading information.

It’s even possible to call it “fake news” in the shoe industry. In all earnestness, it is vital to comprehend the distinctions because then you know what to look for when purchasing shoes and what to anticipate from them in the big scheme of things.

Which one of these processes is the best? If only answering these questions was that easy!

“Goodyear is best,” is a simple but not totally correct response. In many ways, this stands to reason.

It’s a more sustainable concrete technique that allows for more resoling and a longer lifespan than a Bench welt-constructed shoe. Sure, they’re more pricey, but the added value supersedes the extra cost.

The method, as the name implies, is remarkably similar to the above said Goodyear construction, with the exception that the welt seam is done handcrafted and explicitly to the insole.

2 Goodyear Welt Shoes to Buy

GOLDEN RETRIEVER Work Boots

Steel toe, keep your toes safe from harm.

RUBBER outsole is acid and alkali resilient, oil impervious, and non-skid, making it suitable for hotels and restaurants.

Pros:

- Aside from the actual warmth provided by insulated boots, another significant advantage is their durability.

- When purchasing anything, durability is critical, and if you don’t get a long-lasting product, you’ll end up wasting your money replacing it.

- Because these boots are designed to be worn and function during cold temps, the fabric used to make them is made to withstand these conditions.

Cons:

- In fact, your feet can become so hot–especially when performing strenuous tasks–that they overheat, sweat, and are generally uncomfortable to work in.

- They are a little pricey.

- They can be bulky and heavy at times.

Thorogood American Heritage

The American Heritage Moc Toe Shoes are extremely durable. These boots, one of the greatest styles, get the task done – just like the men who flaunt them.

Moc toe boots have a sturdy, iconic style that fits in on the worksite but also looks really good off the clock, thanks to Goodyear storm welt fabrication and sturdy leather.

A detachable Ultimate Shock Permeability footbed on a Poron comfy padding insole keeps you moving throughout the day, and the outsole improves momentum on slick floors.

These tough leather toe boots come in 6” and 8” shaft lengths and have toe safeguard and waterproof alternatives.

Tobacco oil-tanned, Trail Crazyhorse, black, or black walnut leather are accessible at various heights; not all shades of color are accessible at all heights.

2 Bench Welt Shoes to Buy

Park Avenue Cap-Toe Oxford

A strong 360o bench welt construction and a significant cap-toe shape lend it smart adaptability that epitomizes classic American footwear prototype.

This is the ultra-refined dress shoe that everyone needs in their closet, as worn by business leaders, cultural icons, as well as several US presidents.

It is a Lace-up balmoral dress shoe and looks sharp and sophisticated dressed up or down. Take your normal size for a classic fit.

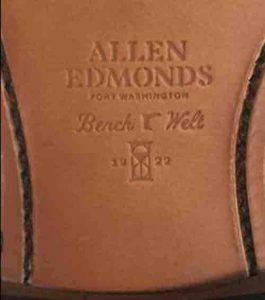

Allen Edmonds Derby Oxfords

They should last you for many years if you assume responsibility for them and wear them in cycle with other shoes.

Remember that you can send them back to the manufacturer in Port Washington for around $100 to $150 per pair to have them re-crafted, prolonging their life even further.

Nonetheless, their overall appearance is conservative and not quite as stylish as some other British or Italian models available today.

Conclusion

Before assessing each variety of shoe fabrication, consider your tastes, how you move, the wear and tear your shoes endure, how you hold your weight, your stride, your shoe behavior patterns, how frequently you will resole them, and how you will genuinely use and retain the footwear.

The construction simply refers to how the sole is connected to the insole and upper. Making the presumption that sturdiness will be swayed solely by this factor is an oversimplification of a rather intricate craft.

The durability of a shoe will be comparable if it is created to the same benchmarks and the only distinction is how the soles are connected.

Related: